- Product category

-

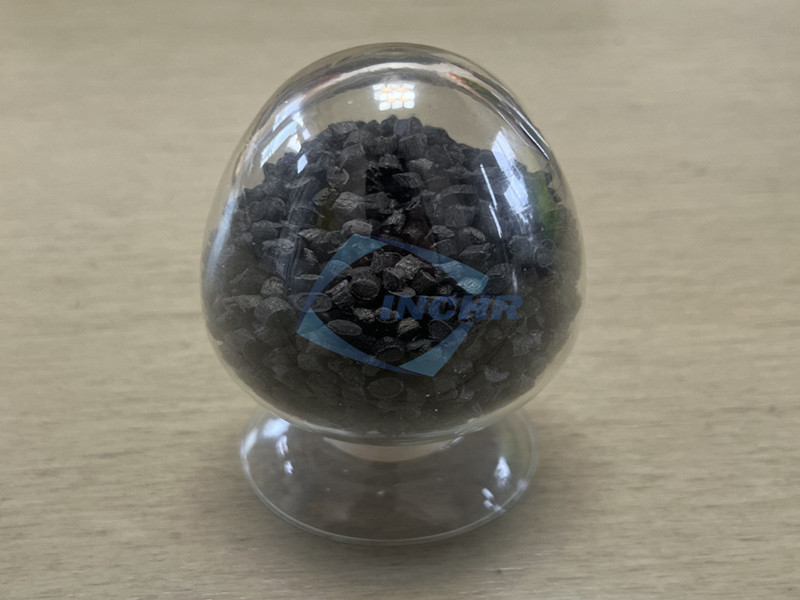

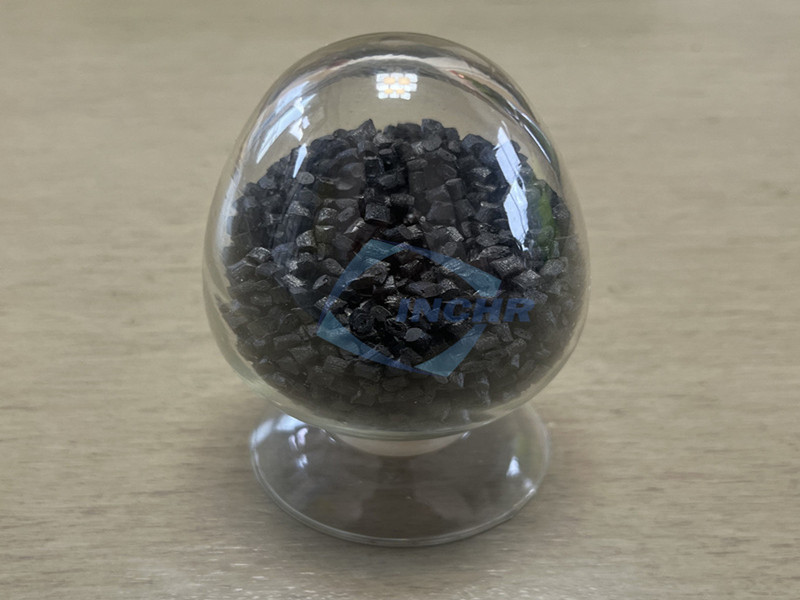

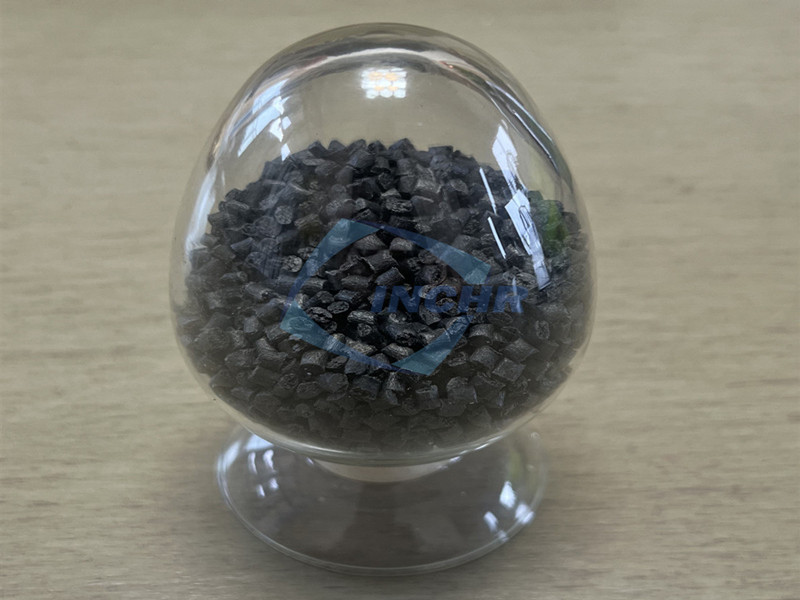

Product name:15% Carbon Fiber ABS

Product model:Carbon Fiber Reinforced Compound

Product brand:INCHR

Processing customized:15% Carbon Fiber Reinforced

Product specification:ABS 150KC

Product description:ABS 150KC Compound

15% Carbon Fiber Reinforced ABS

Electrically Conductive ABS Compound

Properties & Data Of Injection Molded Specimens

Physical property

Standard

Value

Unit

Density

ASTM D792

1.18

g/cm3

Shrinkage

ASTM D955

0.4~0.6

%

Melt Volume Rate

ASTM D-1238

13

g/10min

Mechanical behavior

Standard

Value

Unit

Tensile Strength

ASTM D638

66

MPa

Flexural Modulus

ASTM D790

3100

MPa

Izod Notch Impact 3.00mm

ASTM D256

75

J/m

Thermal

Standard

Value

Unit

HDT(temp. Of deflection under load 1.80MPa)

ASTM D648

120

°C

Electrical properties

Standard

Value

Unit

Surface Resistivity

10E4~10E7

Ω

Flammability

Standard

Value

Unit

Flame Rating 1~1.5mm

UL94

HB

Processing Condition

Value

Unit

Drying Temperature

90-110

°C

Drying Time

3-4

hrs

Melt Temperature Optimum

220

°C

Max. melt temperature

240

°C

Carbon fiber reinforced ABS features

ABS 150KC is one of carbon fiber reinforced ABS series which is 15% carbon fiber filled.

Light weight ,low cost and recyclable.Carbon fiber reinforced ABS compound is lighter than metal, effectively reducing product weight.

High mechanical strength and good heat resistance, the long-term use temperature can reach 80°C, and it maintains good mechanical properties under thermal conditions. At the same time, its excellent mechanical properties and dimensional stability

Excellent anti-static and conductive properties. Due to the conductive properties of carbon fiber, carbon fiber reinforced ABS compound can effectively prevent the accumulation and adhesion of static electricity, and also has good electrical conductivity. Different contents of carbon fiber filling can be used in conductive occasions.

Good chemical resistance. Due to the use of special additives, carbon fiber reinforced ABS compound shows high stability in terms of chemical corrosion and can withstand the erosion of various solvents and corrosive liquids.

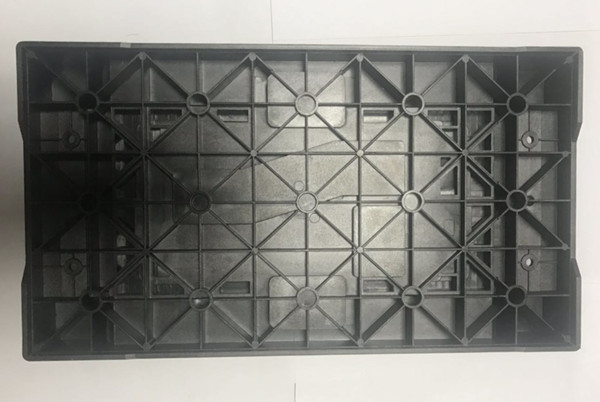

Carbon fiber reinforced ABS applicationsAuto parts manufacturing:Carbon fiber reinforced ABS compound can greatly improve the rigidity and strength of automobile bodies and parts. In addition, its anti-static and conductive properties can also effectively prevent electronic components from being damaged by static electricity.

Electronic device manufacturing:Carbon fiber reinforced ABS compound has good anti-static properties and conductivity, which can effectively suppress the harm caused by electrical electrostatic discharge and ensure the safe operation of electronic components.

Aerospace field:Carbon fiber reinforced ABS compound has the characteristics of low density and light weight, which can make the structure of the aircraft stronger, more durable and faster. At the same time, due to its anti-static performance, it will not cause any damage to the electronic protection of the aircraft.

3D printing modeling:Carbon fiber reinforced ABS has outstanding mechanical strength and good thermal stability, which can ensure the quality and reliability of 3D printed parts.

Mold design and manufacturing:Compared with other carbon fiber reinforced poymers, carbon fiber reinforced ABS compound has good mechanical properties and high fluidity in processing. It is often used as the first choice raw material when manufacturing high-precision, complex-structured molds.

Pre:NothingNext: 20% Carbon Fiber PC